Heat Transfer Fluids

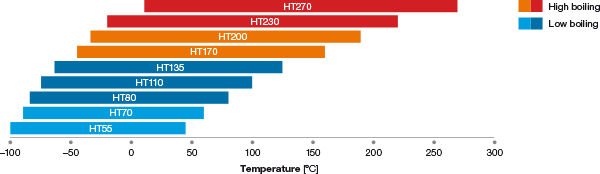

Galden® HT PFPE fluids are inert, dielectric, heat transfer fluids with boiling points ranging from 55°C to 270°C, providing a wide choice of fluids to optimize performance. They are widely used in the Semiconductor and Electronics industries when non-conductive, low-viscosity fluids that withstand thermal extremes are required for thermal exchange systems, testing equipment and server cooling.

High Boiling (HB) grades operate from 150°C to 290°C. They can be used to replace liquids with higher evaporation rates, thereby reducing cost. Because Galden® PFPE fluids are inert, they are ideal for electronic cleaning applications.

Suggested operating temperature range

Galden® HT fluids are compatible with most construction materials used in heat exchangers. Galden® PFPE systems are practically maintenance-free and present no corrosion hazard. Dielectric properties do not change with use, eliminating the risk of short-circuiting. Environmentally safe, Galden® PFPE is non-toxic, non-explosive, and has no flash, fire or auto-ignition points.

Vapor Phase Soldering

Vapor Phase Soldering (VPS) is the process used to mount semiconductor chips to printed circuit boards. This method uses the latent heat of condensation of Galden® PFPE vapors to melt solder paste and form reliable metal joints.

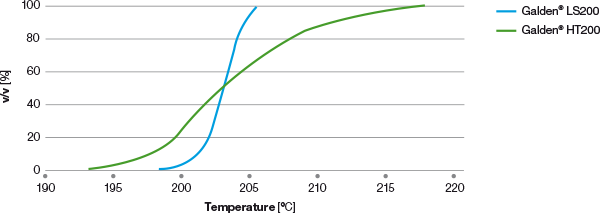

More precisely, Galden® LS and HS grades (LS/HS) provide a lead-free solution for VPS processing up to 260°C. The precise vapor temperature of Galden® PFPE eliminates overheating. The narrow molecular weight distribution eliminates the evaporation of low boiling components and undesired boiling point drift during processing.

Galden® LS/HS grades provide the broadest temperature range of lead-free solutions that are able to withstand higher processing temperatures. These materials are RoHS compliant.

Galden® LS/HS grades offer a broad temperature range

Thermal Shock Testing

Electronic device manufacturers use thermal shock testing to check the resistance of electronic devices to extreme temperature changes. The test is carried out by alternately dipping the devices in a hot fluid and a cold fluid.

Thermal exchange systems use either direct contact single fluid or double fluid coolants. Galden® D products can be used in both systems. In dual fluid systems, two different fluids are used for hot and cold baths. This process has several disadvantages, including high fluid loss in the cold bath, cross contamination between the two baths, equipment downtime and dual fluid inventory.

Galden® PFPE can also be used in single fluid systems, which use the same fluid in both baths. This can significantly lower operating costs by reducing fluid consumption and equipment downtime, eliminating cross contamination, and simplifying inventory.

Hermetic Seal Testing

Electronic devices must be hermetically sealed to prevent moisture absorption, thus damaging the electrical response of the silicon chip. Leak testing is used to check if a device is completely sealed. Because Galden® PFPE fluids are inert and do not leave a residue, they are widely used as detector and indicator fluids in leak test procedures.

Galden® D detector fluids have a good balance between low and high boiler components, making it possible to detect large and small leaks alike. High boilers enter through large leaks and remain liquid until the test is performed while low boilers can easily penetrate into small leaks.

Galden® D low-consumption indicator fluids provide a higher boiling point and lower vapor pressure at test temperatures.

Solvents

Galden® SV grades are low molecular weight, CFC-free solvents that are inert, non-toxic, odorless and colorless.

These products are extremely safe because they have no flash, fire or auto-ignition points. Being chemically inert makes it ideal for cleaning operations where solvents are applied to hot components, heated prior to application or pressure sprayed onto components.

Galden® SV is also used as a carrier for fluorinated lubricants, as is the case for Syensqo’s Fomblin® PFPE lubricants.

Fuel Cells

Galden® HT heat transfer fluids are considered one of the safest dielectric fluids used to manufacture fuel cells due to their high thermal stability, chemical inertness and absence of flash and fire points (FM approved 6930).

Find Galden® PFPE grades, technical data sheets, SDS and more

Find Galden® PFPE products by chemistry, market, application, etc.